Focus On The Axminster Weave

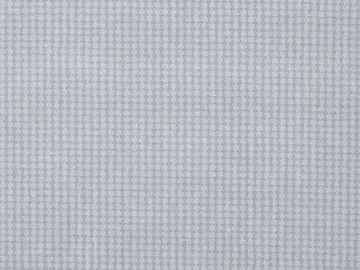

The quality of a woven carpet is defined by the number of holes per square inch, called the "pitch". Also, the way the holes are arranged, either as perfect squares or rectangles. The size of these holes dictates the thickness of the thread to be used. A thicker yarn produces a more intense texture underfoot.

At Axminster, we make our carpets using the best pitch available per feature or design of the carpet. Our highest domestic pitch is an 8 x 10, eight columns across and ten rows down per square inch, with a staggering 80 tiny holes per square inch to weave the yarn through!

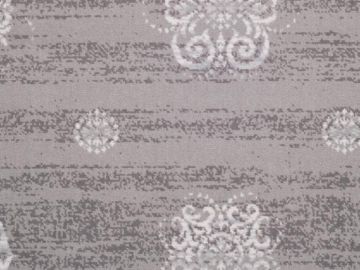

Our most popular pitch for a designed carpet is our unique 8 x 8 pitch, with 64 tiny holes per square inch. It is a perfect square, so designs can include perfect circles or squares where all the lines are the same thickness, whilst diagonal lines flow smoothly.

This kind of precision and detail is impossible with a rectangular pitch like the 7 x 9 used by most other manufacturers.